Large energy-saving industrial ceiling fan

W.Fans

W. Fans series industrial fans are new HVLs energy-saving super large industrial fans independently developed by Dawang ventilation based on PMSM (permanent magnet synchronous motor) permanent magnet synchronous principle, with 260n M stable torque, stronger driving force and more stable torque. It meets the IE4 high efficiency and energy saving standard and saves energy consumption by 30%. The fan diameter is from 3.1m to 8m, and the full load air volume is up to 15072m / min.

-

8

MFan Dia

-

1.2

kw/hAverage energy

-

2462

m²Coverage area

-

15072

m³/minFull speed

Application case

Four advantages

-

- Power system: PMSM permanent magnet synchronous motor

- 1.Stronger: 260n M amazing torque, stronger driving force and more stable torque;

2.More efficient: unique external rotor high torque design, higher control accuracy;

3.More energy saving: save energy consumption by 30%, reach IE4 high efficiency and energy saving standard, and reach the new level of national energy efficiency standard gb30253-2013;

4.Lifelong maintenance free: completely sealed without replacing lubricating oil, oil seal and other accessories, saving a large amount of later maintenance costs;

5.Quieter: 38dB ultra-low volume, only the sound of wind in your ear;

6.Low temperature rise: the temperature rise of the motor is lower than 35 ℃, and the service life is longer!

-

- control system: vector frequency conversion control

- 1. More stable: the new generation of high reliability IGBT module, motor vector algorithm and current suppression processing mode make the start more stable

2.Quieter: carrier frequency up to 16KHz, without any electromagnetic noise during acceleration, deceleration and operation;

3.More reliable: PCBA three proof paint treatment, durable;

4.Smooth restart: the smooth restart function can be realized when the fan blade does not stop completely;

5.25 kinds of fault protection: up to 25 kinds of fault protection functions (overcurrent, overvoltage, undervoltage, over temperature, phase loss, overload, etc.)。

-

- Patented blades: fan airflow components

- 1.Blade design - streamlined variable section

Applying the theory of equal chord length of aerodynamics and the principle of relative linear velocity, the blade root to blade tip gradually narrows (304-186mm) and thins (43mm-21mm), the force is more balanced, the air supply is more uniform, and there is no cavity in the center.

2.Blade material - aviation industry plate

It adopts 5052h32 high-grade 1.5mm aviation grade aluminum alloy motherboard, which is formed by precision numerical control, with higher strength and flexibility to ensure no fracture.

3.Blade weight - lighter and safer

Each blade is only 6.7 kg (7.3 m in diameter, excluding buffer parts). The number of blades is small, the weight is light, the motor load is reduced, the service life is prolonged, and it is safe and energy-saving.

-

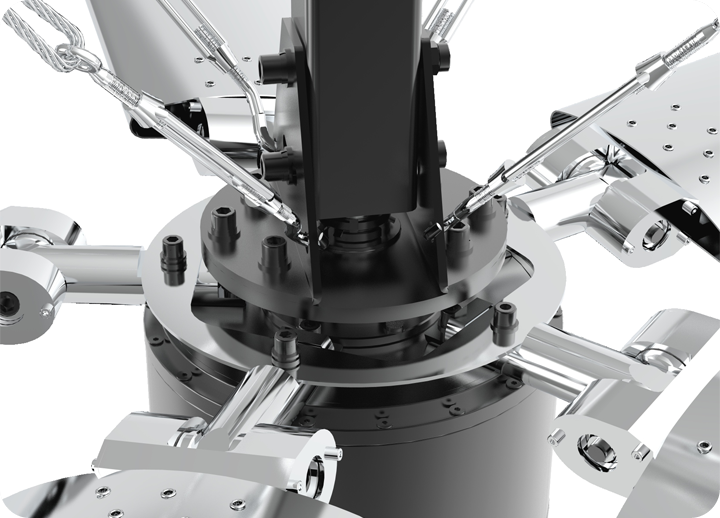

- Structural connection: patented structural design of key parts of tenon and mortise connection

- 1.Connection between blade and petiole

Tenon and mortise connection: the "concave" section of the blade handle forms a joint bite with the "convex" section of the buffer, so as to eliminate the outward centrifugal force of the blade during the operation of the fan and the shear force during the start and stop of the fan;

The transverse screw is fastened in the same direction as the running track of the fan, free from right angle shear force, so as to ensure that the blade is not broken and fundamentally eliminate the potential safety hazard of secondary injury.

2.Connection between blade handle and hub

Through the mutual engagement of stepped concave convex sections, the blade handle is integrated with the hub / motor. The overall structure is used to bear the centrifugal force during the operation of the fan, and all fasteners are not stressed.

3.Connection between motor and flange

Safety ring: connect the five leaf petioles with the upper cover of the motor, and use the structural bite mode to realize the stress of the overall structure;

Anti falling disc: the "concave" section of the flange and the "convex" section of the anti falling ring are engaged and hooked with each other under the action of gravity to ensure the reliable connection between the motor flange and the motor.

Insurance

-

Design of streamlined variable section blade

Applying the aerodynamic equal chord length theory, combined with the principle of relative linear velocity, the blade root to blade tip gradually narrows and thins, the force is more balanced, the air supply is more uniform, and there is no cavity in the center.

-

Aviation grade anti-collision blade material

1.5mm thick 5052 aviation aluminum plate, which can withstand tensile force of more than 3 tons and ultra-high material toughness, ensures that the blade can change quickly when impacted, effectively absorbs external force, prevents blade fracture, and greatly avoids damage to motor and other structural parts。

-

High strength riveting of blade

Each blade is riveted with 16 high-strength rivets up and down with the buffer cavity to form an independent surface. The design shear capacity of each rivet is 1.5T.

-

Shock absorber

The blade handle and blade are non rigidly connected by damping device, with special vibration isolation rubber pad to absorb the vibration generated by most of the blades when the fan is running.

-

Anti falling disc

The "concave" section of the flange plate and the "convex" section of the anti falling ring are engaged and hooked with each other under the action of gravity to ensure the reliable connection between the motor flange plate and the motor。

-

Safety ring

Connect the five leaf petioles with the upper cover of the motor to ensure that the leaf petioles will not separate and fall。

-

Tenon and tenon type petiole connection

Tenon and mortise connection: the "concave" section of the blade handle forms a joint bite with the "convex" section of the buffer, so as to eliminate the outward centrifugal force of the blade during the operation of the fan and the shear force during the start and stop of the fan.

-

High tensile strength petiole material

6061-T6 petiole, with high strength and hardness, can reach more than hb90 degrees, has good corrosion resistance and can withstand 205mpa tensile strength.

-

Wire rope winding protection

The mounting plate and beam are wound with 1000kg tensile steel wire rope to ensure that the overall structure of the fan is not loose and does not fall.

-

Wire rope balance protection

The four steel wire ropes are fixed with the building traction based on the balance principle to ensure that the fan is not shaken and dropped by external force and air flow.

-

Abnormal alarm system

The frequency conversion control system is equipped with over-voltage, overload, loss and other accidental protection. In case of abnormality, it will automatically alarm and stop the fan.

-

Real time monitoring and active maintenance

Dawang intelligent remote control system can monitor the equipment operation parameters, motor temperature rise and equipment levelness in real time.

Application occasion

Workshop

Workshop Logistics storage

Logistics storage gym

gym Gymnasium

Gymnasium Indoor playground

Indoor playground The exercise room

The exercise room  Convention Center

Convention Center 4S shop

4S shop Terminal market

Terminal market- Supermarket

- office building

- villa

- Canteen

- Museum

- Business

- Amusement Park

- Zoo

- Playground

- Station

- Metro Station

- air terminal

Product parameters

| Series | W.Fans Series | ||||||||

| Model | W26 | W24 | W22 | W20 | W18 | W16 | W14 | W12 | W10 |

| Specification/ Diameter(m) | 8 | 7.3 | 6.7 | 6.1 | 5.5 | 4.9 | 4.2 | 3.6 | 3.1 |

| Speed(rpm) | 10-45 | 10-55 | 10-60 | 10-60 | 10-70 | 10-75 | 10-80 | 10-85 | 10-90 |

| Full-load air volume(m3/min) | 15800 | 14550 | 13800 | 12600 | 11500 | 10800 | 9280 | 7954 | 6849 |

| Coverage area(m2) | 2462 | 2123 | 1809 | 1520 | 1256 | 1017 | 804 | 615 | 452 |

| Rated power(kw) | 1.5 | 1.1 | 0.75 | 0.4 | |||||

| Average consumption (kW·h) | ≤1.2 | ≤1.0 | ≤0.7 | ≤0.4 | |||||

| Noise(dB) | 39 | ||||||||

| Power supply(V) | 380V/220S | ||||||||

| Full-load current(A) | 2.8(380V)/4.6(220V) | 2.6(380V)/3.0(220V) | 2.5 | 2.0 | |||||

| Total weight(kg) | 108 | 92 | 90 | 73 | 63 | 60 | 47 | 42 | 39 |

*More sizes can be customized | |||||||||

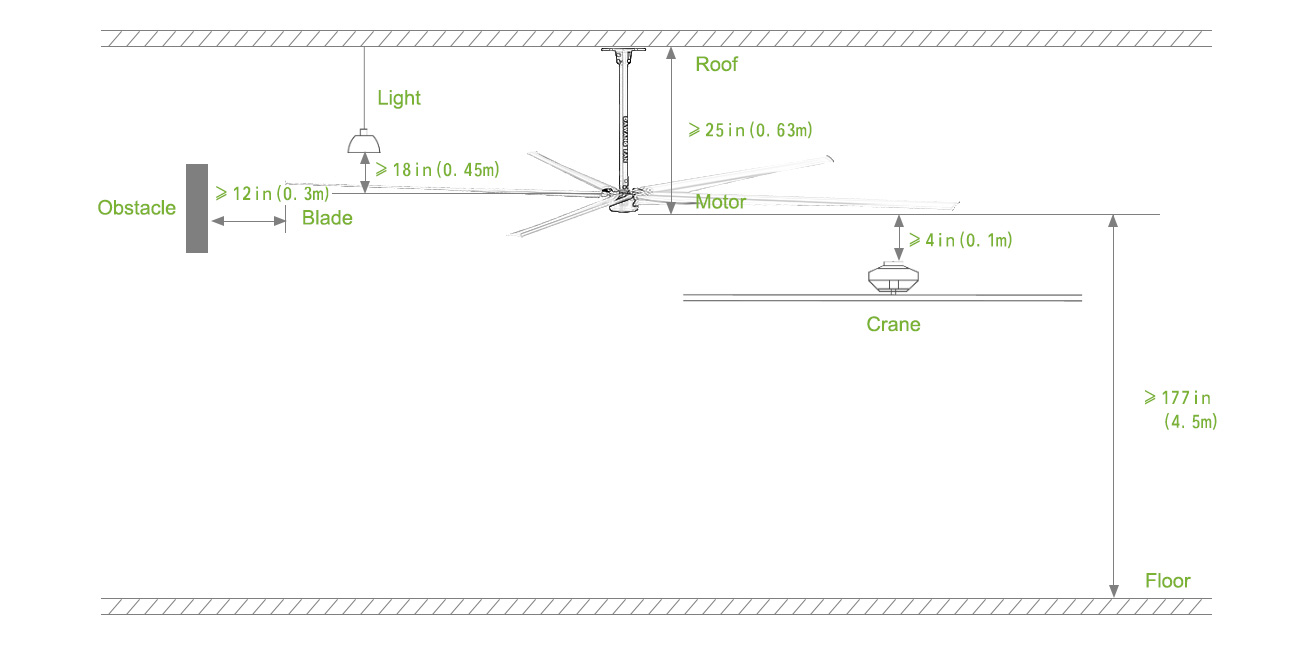

Installation height description