1.Stronger: an astonishing torque of 260N. m, with stronger driving force and smoother torque;

2.More efficient: Unique outer rotor with high torque design, higher control accuracy;

3.More energy-saving: save energy by 30%, meet the E4 high-efficiency energy-saving standard, and meet the new national energy efficiency standard of GB30253-2013

4.Lifetime maintenance free: completely sealed, no need to replace lubricating oil, oil seals, and other accessories, saving a large amount of maintenance costs in the later stage;

5.More muted: 38db ultra low volume, with only the sound of wind in the ear;

6.Low temperature rise: Motor temperature rise below 35 ° C, longer lifespan!

1.Easy to debug built-in application macros, no need for self-learning

2.Excellent performance, perfectly matching the operating parameters of the load motor

3.Low noise operation, optimized algorithm control for smooth start-up

4.Safe and reliable, with built-in multiple protection programs to enhance product life

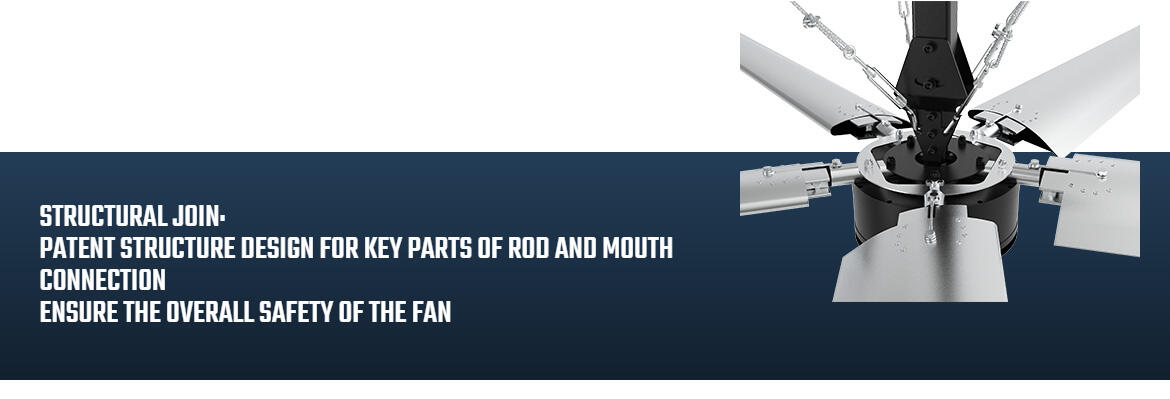

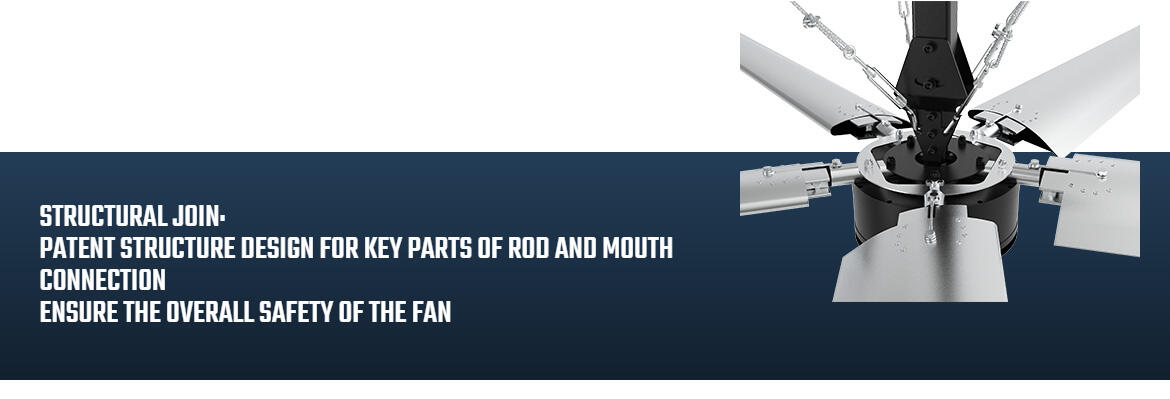

1.Connection between blade and petiole

The blade handle is made of 6061T6 aviation grade aluminum alloy, which is precision processed by 4-axis CNC and wrapped with PU polyurethane (with high resilience, shock absorption, wear resistance, oil resistance, tear resistance, chemical corrosion resistance, and radiation resistance). It is closely matched with the blade buffer chamber to efficiently release the vibration and stress generated by blade rotation, eliminate resonance, reduce motor load, and extend service life.

2.Connection between petiole and wheel hub

By interlocking the blade handle with the wheel hub/motor through a stepped concave convex cross-section, the overall structure is used to withstand the centrifugal force during fan operation, and all fasteners are not subjected to force.

3.Connection between motor and flange plate

Safety ring: Connect 5 blade handles with the upper cover of the motor, and use a structural interlocking method to achieve overall structural stress; Anti drop plate: The "concave" section of the flange plate and the "convex" section of the anti drop ring bite and hook each other under the action of gravity, ensuring the reliable connection between the motor flange plate and the motor.

| Series |

W.Fans Series |

| Model |

W26 |

W24 |

W22 |

W20 |

W18 |

W16 |

W14 |

W12 |

W10 |

| Specification/ Diameter(m) |

8 |

7.3 |

6.7 |

6.1 |

5.5 |

4.9 |

4.2 |

3.6 |

3.1 |

| Speed(rpm) |

10-45 |

10-55 |

10-60 |

10-60 |

10-70 |

10-75 |

10-80 |

10-85 |

10-90 |

| Full-load air volume(m³/min) |

15800 |

14550 |

13800 |

12600 |

11500 |

10800 |

9280 |

7954 |

6849 |

| Coverage area(㎡) |

2462 |

2123 |

1809 |

1520 |

1256 |

1017 |

804 |

615 |

452 |

| Rated power(kw) |

1.5 |

1.1 |

0.75 |

0.4 |

| Average consumption (kW·h) |

≤1.2 |

≤1.0 |

≤0.7 |

≤0.4 |

| Noise(dB) |

39 |

| Power supply(V) |

380V/220S |

| Full-load current(A) |

2.8(380V)/4.6(220V) |

2.6(380V)/3.0(220V) |

2.5 |

2.0 |

| Total weight(kg) |

108 |

92 |

90 |

73 |

63 |

60 |

47 |

42 |

39 |