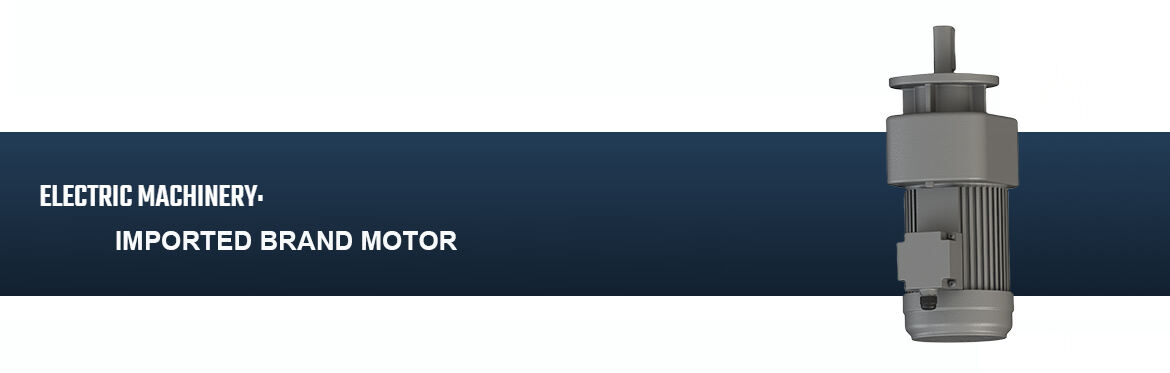

1.High energy efficiency: Meet the IE2 high-efficiency and energy-saving standards, saving 5-10% energy compared to IE1;

2.High reliability: High axial and radial bearing capacity, ensuring operational reliability;

3.Low noise: low backlash assembly process and gear grinding process, with low vibration and lower noise;

4.High safety factor: Strengthen the bearing frame structure, trapezoidal shaft structure, increase oil seal, strengthen the body structure, and achieve higher safety factor;

5.Certified by CCC, CE, UL.

1.Easy debugging, built-in application macros, no need for self-learning;

2.Excellent performance, perfectly matching the operating parameters of the load motor;

3.Low noise operation, optimized algorithm control for smooth start-up;

4.Safe and reliable, with built-in multiple protection programs to enhance product life.

1.5052H32 aviation grade aluminum plate material, 1.5MM thick, with 5 blades capable of withstanding a tensile force of more than 3 tons, without breaking upon impact;

2.Variable cross-section streamline fan blade: the blade gradually narrows from the root to the tip, thins and widens at the tail, with more balanced force, no fracture risk, less wind resistance, more uniform air flow and no cavity in the middle;

3.Lighter and safer: The 7.3 meter fan blade weighs only 6.7KG per piece, making it lighter and safer.

1.Better mechanical performance: Made of 6061T6 aviation grade aluminum material processed by CNC lathe and CNC precision machining process, the appearance remains highly consistent, the metal flow line is completeand the chassis has better mechanical performance;

2.More precise dynamic balance: After CNC machining, the chassis accuracy tolerance is controlled at 100um, ensuring accurate dynamic balance of the chassis.

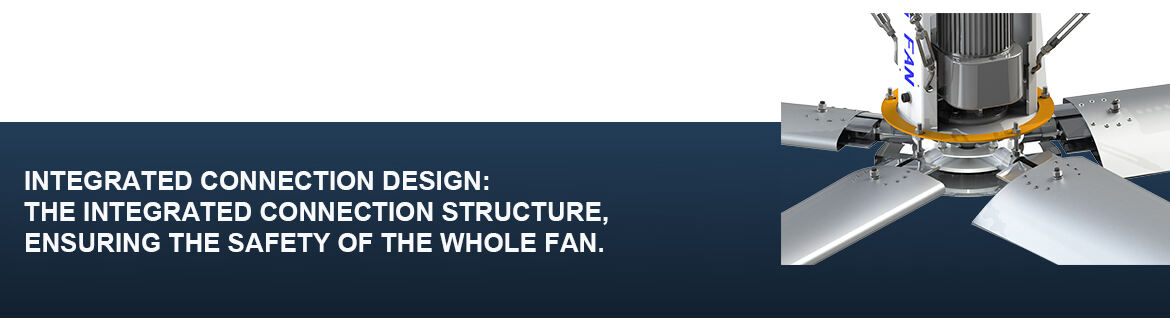

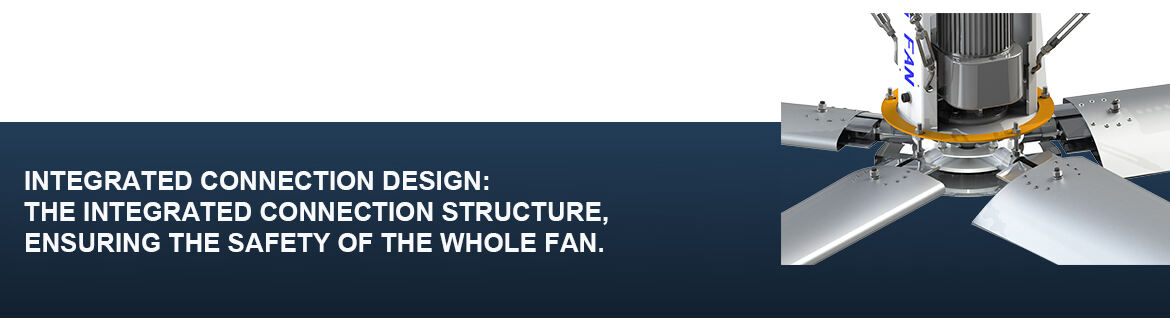

1.Motor and chassis: Tightly connected through inner and outer cones, even if the motor shaft is loose and broken, the inner and outer cones form a structural self-locking to prevent falling;

2.Chassis and blade handle: The blade handle is connected to the chassis through a hook type mortise and tenon joint, and the bolts are not under force, ensuring overall strength;

3.Blade and petiole: closely matched with the blade buffer chamber, efficiently releasing the vibration and stress generated by blade rotation, eliminating resonance, reducing motor load, and extending service life.

| Series |

D.Fans Series |

| Model |

D26 |

D24 |

D22 |

D20 |

D18 |

D16 |

D14 |

D12 |

D10 |

| Specification/Diameter (m) |

7.8 |

7.1 |

6.7 |

6.0 |

5.4 |

4.8 |

4.2 |

3.6 |

3.1 |

| Speed (rpm) |

10-45 |

10-55 |

10-60 |

10-60 |

10-70 |

10-75 |

10-80 |

10-85 |

10-90 |

| Full load air volume (m ³/min) |

16870 |

16130 |

14800 |

14200 |

12800 |

11800 |

10800 |

8900 |

7800 |

| Average consumption (kW · h) |

1.5kw/45rpm |

0.75kw/60rpm |

| Rated power (kw) |

≤1.5 |

≤1.2 |

≤0.7 |

| Motor noise (dB) |

≤50 |

| Full-load current (A) |

3.2 |

2.1 |

| Power supply (V) |

380V/220S |

| Total weight(kg) |

106 |

101 |

99 |

96 |

95 |

90 |

88 |

86 |

82 |