Learn expert tips for selecting cost-effective HVLS fans with optimal airflow and energy efficiency.

Mr. Wang's workshop wants to install a batch of industrial fans to alleviate the summer heat, online search a circle, look at all good, about the sales door-to-door survey quotation, the price is a lot of difference, then the problem comes, which should buy? This industrial fan is quite cheap, do you want to buy?

Why is the price of industrial fans so much worse? What are the factors affecting the price? The following small series to analyze.

First, the security configuration is different

A gentleman does not stand under a dangerous wall! It is the instinct of human nature to seek good fortune and avoid disaster. The fan blades, which are bigger than helicopters, rotate overhead. If there are no safety measures, anyone will be flustered!

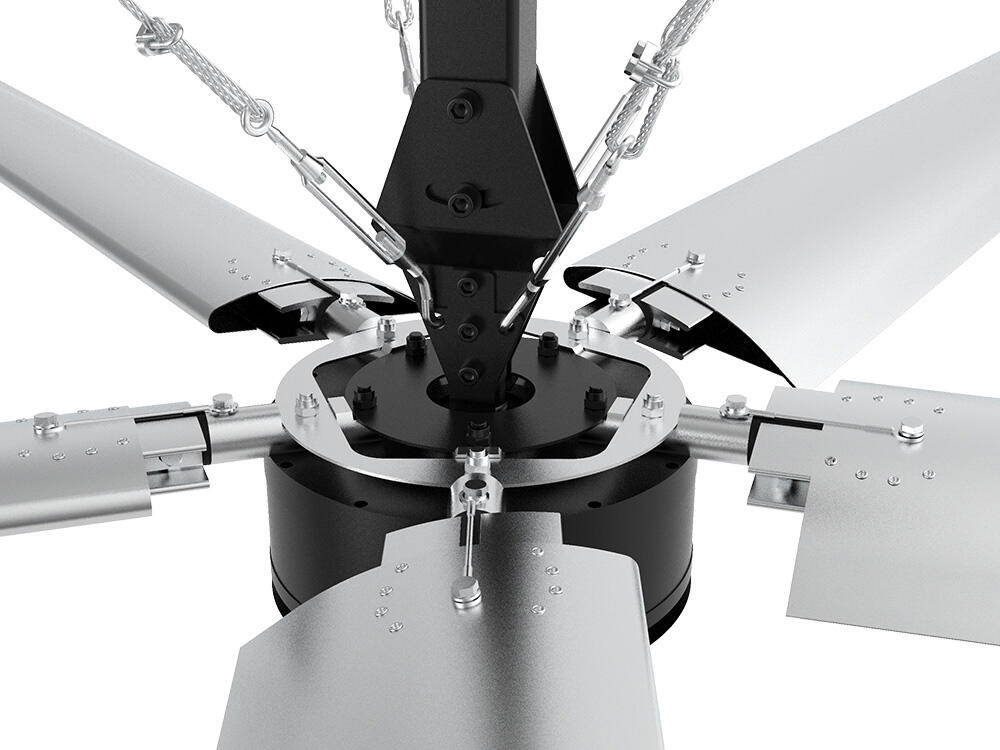

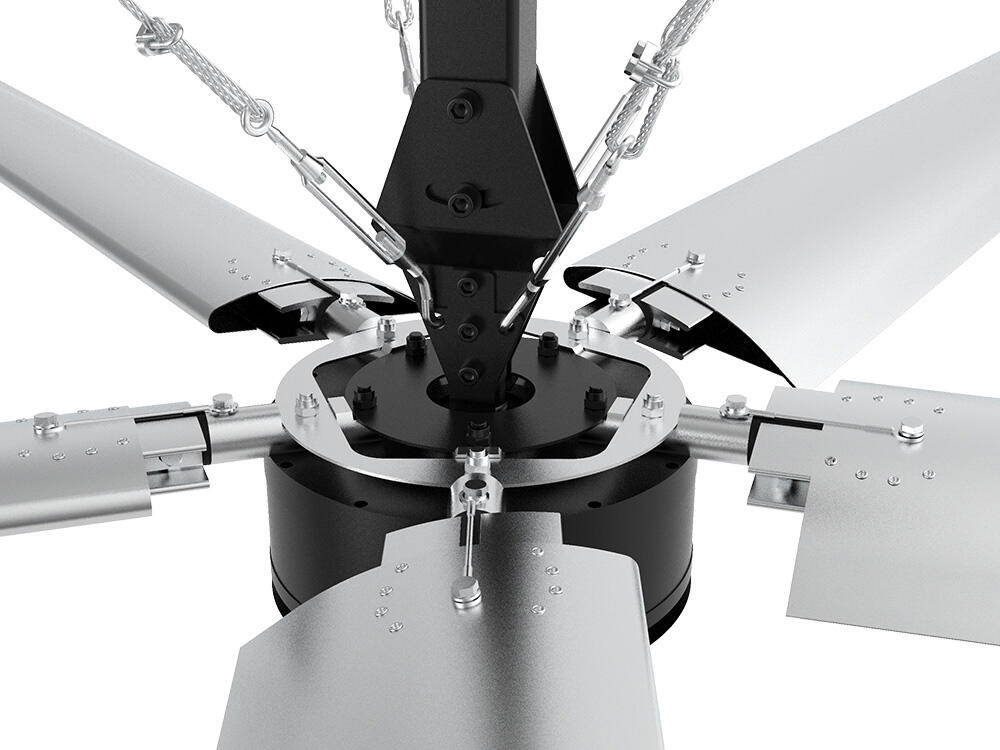

Impactlarge industrial fanThere are many security factors, mainly: connectionStructure, fan bladeDesign Material,Passive safety protection design, control system,Balance protection wire ropeWait.

Different brands of industrial fans have completely different safety configurations. Just like people buying cars, other configurations except for the safety configuration can be deleted, but no one will choose to reduce the safety configuration in order to reduce the purchase cost budget. Because the resulting security risks are completely out of proportion to the cost we save.

No accident caused by passive safety design of a brand

No product is absolutely guaranteed.100%If an exception does not occur, we need to think about how to ensure our security risks when an exception occurs. For example, the passive safety of a car includes seat belts and airbags. When an abnormal car accident occurs, to ensure the safety of drivers and passengers, our industrial fans also need to have corresponding passive safety protection measures to prevent secondary injuries. Hidden dangers.

Good security configuration can play an important role in critical times. To reduce the risks we may face, each brand will introduce its own security measures to customers. Then comes the question! How can we tell whether the safety technology of industrial fans is really reliable?

Look at the brand: At present, there are not many manufacturers specializing in industrial fans in the domestic industry. Many brands of industrial fans are just a sideline. When the market is good, they join in one after another. When the market is bad, they withdraw one after another. This situation will lead to unsustainable service.

Look at the standard: the employees of big brand manufacturers are highly professional, with strict standards and specifications, product standards, installation and construction standards, and after-sales service standards.

Look at services: pre-sales services, such as data collection, model selection, plan formulation, budget evaluation; After-sales service, such as tracking of product usage, regular safety inspection, immediacy of after-sales response and timeliness of problem solving, etc.

Look at the qualification and case: the qualification case can assist us in judging the advantages and disadvantages of the brand.

Competition reference comparison: professional personnel in the same industry can really understand which safety technology is reliable and practical, which safety technology is only to improve the selling point of the product, but does not have complete practical value. Through the comparison of different brand manufacturers, we can get better identification.

Safety is not in place, no matter how cheap it is, you can't buy it! Or you're the next guinea pig!

Second, the material is different

Excellent materials are the basis of product high quality.

IndustryBigFan blades are made of aluminum-magnesium alloy fan blades, aluminum fan blades, iron fan blades, engineering plastic fan blades, etc. Different fan blade materials have their own advantages and disadvantages in terms of weight, life, price, etc,Use5052H32high label1.5mmComprehensive properties of fan blades for aviation grade aluminum alloy mother boardbetterBut the price is also expensive.

Third, the configuration is different

At present, the permanent magnet motor configuration in the industrial large fan market is mainly divided into two categories: outer rotor permanent magnet motor and inner rotor permanent magnet motor.

The inner rotor permanent magnet motor brand manufacturers have been conducting to customers that the heat dissipation performance of the outer rotor permanent magnet motor is not good.

Objectively speaking, there is not much difference between the inner rotor and the outer rotor permanent magnet motor itself in terms of working principle and mechanical performance, but the applicability of the application field is different. Under the same basic conditions, the inner rotor permanent magnet motor The torque is relatively small, and it is more used in areas that require high-speed precise control. The external rotor permanent magnet motor has a relatively large torque and is more suitable for equipment with relatively constant speed and low speed.

Regarding heat dissipation, we have to mention"Temperature rise", temperature rise refersRising temperature when the product is operating under normal or fault conditions. When the motor torque, power and operating environment are the same, the main factor that determines the temperature rise is the size of the equipment operating load, so when comparing the heat dissipation effect, the first thing to consider is the size of the equipment operating load. For example, a certain brand of motor is equipped with a heat sink to enhance the heat dissipation effect, which is beyond doubt from the design principle and effect. However, if we judge from the business logic, we will come to a completely different conclusion: the increase of any product component means the corresponding increase of cost. For example, when ensuring the stable operation of the product does not have adverse effects on the product, why add another component, both increase the cost and increase the risk.

Selection of core materials for permanent magnet motors

The core material grade determines the difference of the heat resistance coefficient of the permanent magnet motor, and under the same operating environment, the temperature rise is the same, and the difference of the heat resistance coefficient of the material affects the stability of the equipment quality. The higher the material grade, the higher the heat resistance, and the production cost increases accordingly.

About the safe configuration of permanent magnet motor

The structural characteristics of the outer rotor motor facilitate the configuration of the passive safety protection structure. When the motor breaks the shaft and loses the shaft, the corresponding safety measures are needed to prevent secondary damage. According to the results of market research, the current inner rotor motor is not equipped with the corresponding safety structure. When we choose a product, when considering the performance of the equipment, we must first consider its safety performance. There is no guarantee for safety, and we cannot choose any cheaper product.

Outer rotor permanent magnet motor industrial large fan

If the motor is the heart of the big fan, then the frequency converter is the brain of the big fan. The performance of the inverter directly affects the overall operation and energy-saving effect of the industrial fan, and its importance is self-evident.

The frequency converter on the market is mainlyThere areTwo kinds: curve point teaching programming program control inverterandDigital vector frequency conversion control frequency converter. There is little difference in appearance between the two, it is difficult for ordinary consumers to distinguish clearly, and sales merchants will not deliberately explain.

The curve point teaching programming program controls the frequency converter through simple setting and simple operation program, which is prone to jitter or even reverse rotation when starting and stopping, and the protection function is simple, which is prone to overload burning of the motor.ofThe problem.

Digital vector frequency conversion control frequency converter with servo function, strong electromagnetic accounting ability, can accurately control the motor start and stop position, start and stop soft curve, effectively eliminate noise and vibration, at the same time with multiple power protection,havePowerful overload protection capability.

Digital vector frequency conversion control inverter

At present, the mainstream industrial large fan blades are divided into streamlined variable cross-section fan blades and equal cross-section fan blades. Due to the inconsistent force between the root and tip of the large fan during operation, the air output and safety factor of the fan blades are greatly affected by the design. The equal cross-section fan blade will have the phenomenon of middle cavity when the wind is out, and the uneven force is easy to cause the fan blade to break, and the streamlined variable cross-section fan blade can solve these problems.

Broken constant section fan blade

Fourth, production, installation and service are different

The control of the production process is mainly monitored by national standards, suchISO9001,CE,ROHS,FCCOn the other hand, some "high-tech enterprises" and patent certificates also reflect the level of technology of the enterprise.

The specification of the installation process can also reduce the risk factor in the use of industrial large fans.

After-sales service is another major factor affecting the price of industrial fans. After all, no one wants the fan to hang up for two or three days, and then the manufacturer shirks its responsibility and ignores it."Five-star after-sales service qualification certification" manufacturers will be more popular.

The operating life of the manufacturer is also a factor to be considered, so as not to complain when looking for after-sales service.